Introducing an Innovative 3D Printing De-Powdering Post-Processing

The story begins about three years ago, when one of our customers was looking for a metal printer with a capacity of 5,000 parts per month. We offered the Desktop Metal P50. From the very beginning, it became clear that de-powdering the build bed would pose significant challenges in terms of labor and cost. That insight led us to develop the De-Powdering machine.

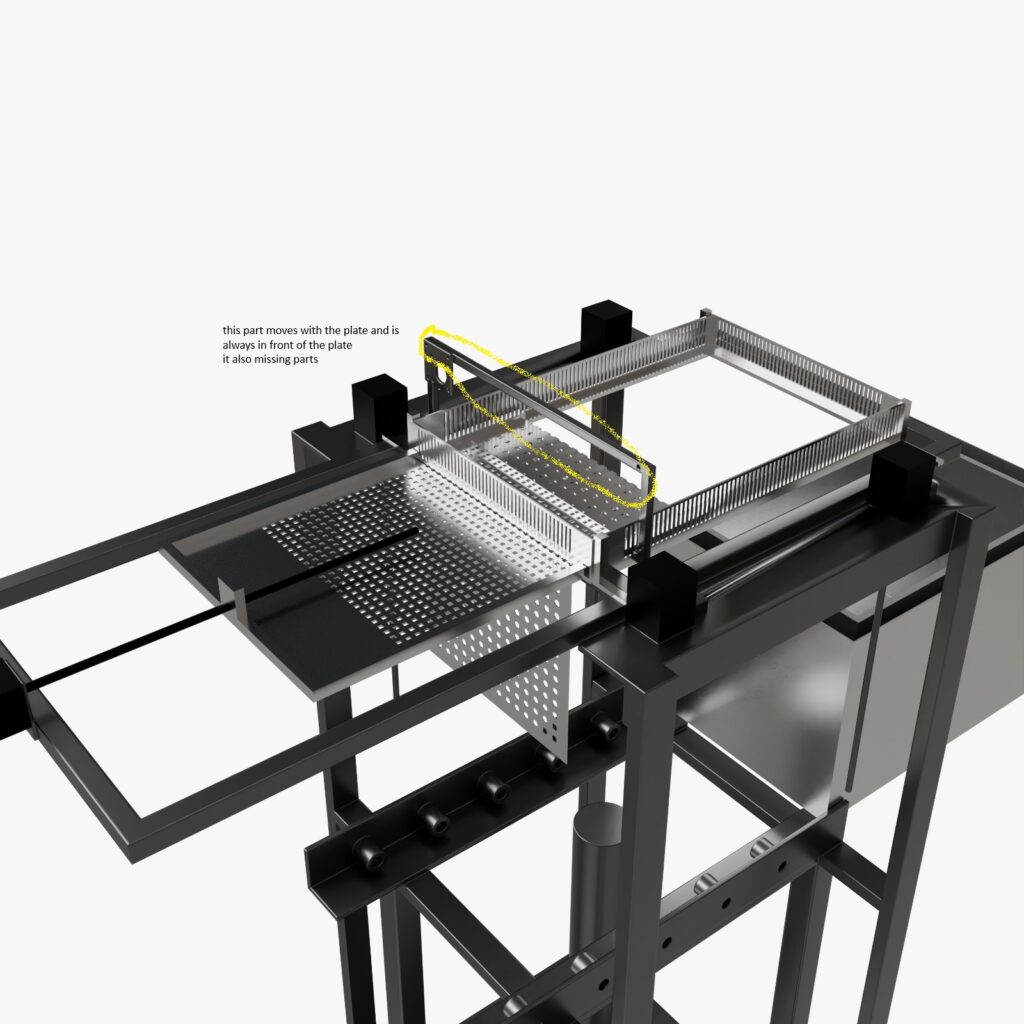

During the development of the machine, we encountered several design challenges. One of the main issues that held us back was the behavior of the powder during the insertion of the perforated surface into the job box at predefined intervals,. As the surface was pushed in, the powder shifted along with it—being dragged forward and upward—which in turn moved the printed parts and risked damaging them.

After extensive thought and experimentation, we managed to devise a simple yet effective and affordable solution that resolved the issue.

The solution was to attach a Teflon sheet to the perforated surface. As the surface moves forward, it pushes the Teflon sheet along with it. This mechanism ensures that the top layer of powder remains undisturbed. Since the penetration is driven by the Teflon being pushed forward, friction with the powder occurs only at the lower part of the perforated surface. However, because we added a thin strip at the top edge of the perforated surface, friction is virtually eliminated even at the rear side.

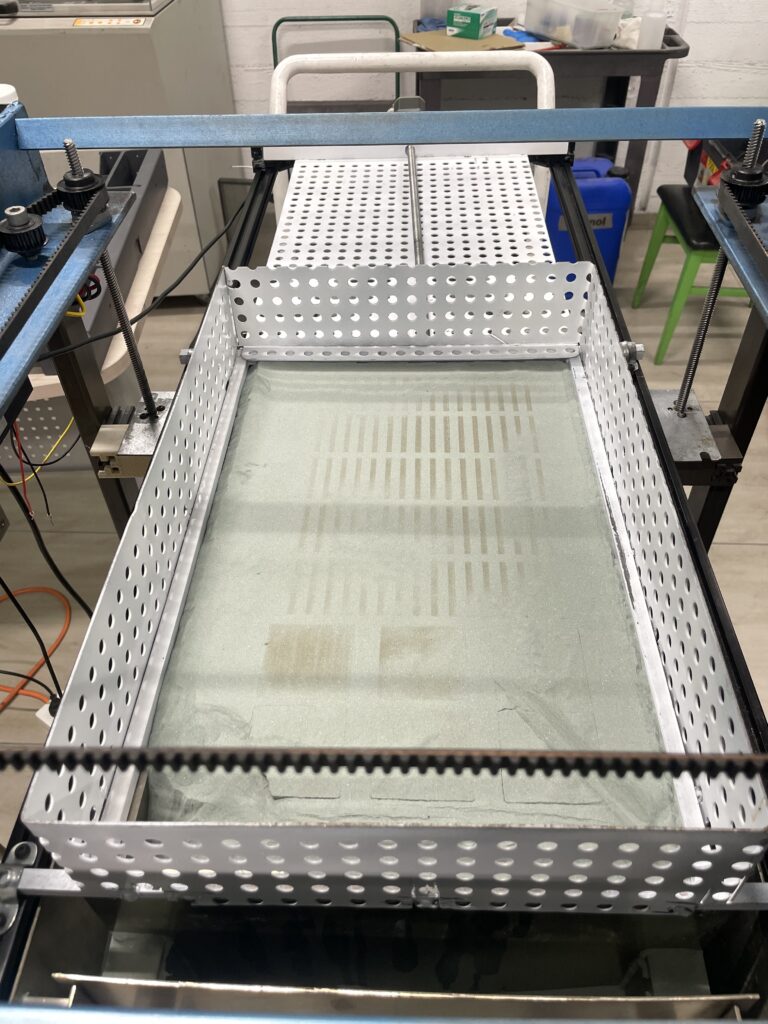

We then built a prototype to test the surface penetration, and the results were highly successful. See the attached video for a demonstration.

3 years later, we are excited to present a groundbreaking system that automates the de-powdering and extraction of 3D printed parts

🔧 Key Features

Fully Automated De-powdering: Efficient powder removal with vibration and pressure, no manual labor

Smooth Insertion Process with Teflon: Reduces friction, prevents part damage.

Reusability: Collected powder is reused, environmentally friendly.

Precision Extraction: Gripper system for safe handling of fragile parts.

To take this solution forward and build the first full-scale machine, we are currently seeking investors and strategic partners. If this topic interests you, we would be happy to connect.

The following video simulates the final version of the machine.

Let's connect and discuss how we can collaborate to bring this innovation to life. Together, we can make 3D printing more efficient, sustainable, and scalable.

Feel free to reach out via contact or email if you're interested in learning more or investing in this exciting venture!